From Gears to Idlers: The Complete Remedy for Trustworthy Undercarriage Parts

From Gears to Idlers: The Complete Remedy for Trustworthy Undercarriage Parts

Blog Article

Optimize Efficiency With Long Lasting Undercarriage Components

In the realm of heavy machinery and tools, the duty of undercarriage parts is paramount in making sure optimum efficiency and durability. The performance and performance of these parts can substantially influence the overall operation of equipment, making the option of long lasting undercarriage parts an essential decision for operators and supervisors alike. By checking out the elaborate relationship in between longevity and performance in undercarriage components, a much deeper understanding of the subject arises, shedding light on the pivotal aspects that drive functional success. As we browse with the intricacies of undercarriage part, long life, and maintenance selection, an extensive expedition awaits to unveil the key methods for attaining peak efficiency in sturdy applications.

Benefits of Using Sturdy Undercarriage Components

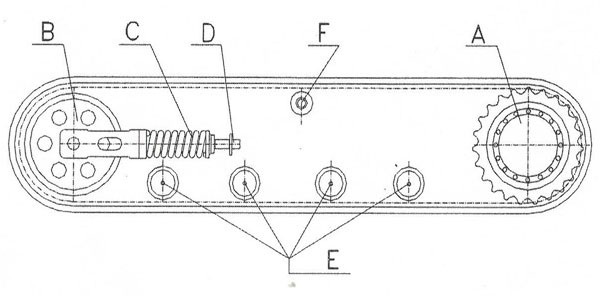

Using durable undercarriage components not just improves the long life of heavy machinery but also decreases upkeep costs dramatically. By buying high-quality undercarriage elements, such as tracks, sprockets, idlers, and rollers, equipment operators can experience boosted uptime and boosted general performance.

In addition, the long life of heavy equipment is directly connected to the quality of its undercarriage components. Long lasting parts can stand up to the rigors of demanding applications, making sure that the equipment stays functional for prolonged durations. Therefore, operators can prevent costly downtime and upkeep costs, inevitably maximizing the roi for their equipment.

Elements Influencing Undercarriage Longevity

The longevity of undercarriage components in hefty machinery is influenced by various important elements that directly effect performance and durability. Premium products, such as hardened steel, are crucial for withstanding the severe conditions and heavy lots that undercarriage parts are subjected to - undercarriage parts.

Furthermore, ecological elements can have a significant effect on the long life of undercarriage parts. Direct exposure to abrasive products, severe temperature levels, and rough working conditions can increase deterioration on undercarriage parts. Picking undercarriage components that are especially designed to stand up to these environmental challenges is vital for making sure sturdiness.

In addition, the design and engineering of undercarriage components have a direct influence on their toughness. Components that are created to disperse lots evenly, decrease friction, and minimize anxiety concentrations are most likely to have a much longer lifespan - undercarriage parts. By taking into consideration these critical aspects, devices operators can take full advantage of the resilience and performance of their undercarriage parts

Upkeep Tips for Prolonging Undercarriage Life

Implementing normal upkeep regimens is vital for prolonging the life expectancy of undercarriage parts in heavy equipment. In addition, guarantee that the undercarriage is appropriately lubed according to producer guidelines to minimize friction and avoid premature wear.

One more crucial maintenance pointer is to keep the undercarriage clean from dirt, rocks, and particles. Build-up in the undercarriage can accelerate wear and corrosion, leading to expensive repair work. Washing the undercarriage after operation in harsh conditions is suggested to stop these concerns.

Lastly, monitoring and recording upkeep tasks can aid in developing a Related Site positive upkeep schedule. Maintaining thorough documents of substitutes, fixings, and examinations can provide valuable understandings into the undercarriage's problem and efficiency with time, helping in predicting and stopping possible failures. By following these upkeep ideas diligently, operators can dramatically raise the toughness and efficiency of undercarriage components in hefty machinery.

Picking the Right Undercarriage Parts

Selecting appropriate undercarriage parts is vital for optimizing the performance and long life of heavy machinery. When it pertains to choosing the appropriate undercarriage elements, there are a number of variables to think about. One essential aspect is comprehending the particular needs of the equipment and the setting in which it will certainly run. Different applications may ask for various kinds of undercarriage elements, page such as tracks, idlers, rollers, and sprockets. It is important to pick parts that are designed to endure the specific problems the equipment will certainly encounter, whether it be rough surface, rough products, or extreme temperatures.

Deciding for respectable brands understood for generating high-performance and resilient undercarriage components can dramatically impact the overall efficiency and long life of the equipment. By thoroughly picking the ideal undercarriage components, devices proprietors can improve performance, reduce downtime, and expand the life-span of their hefty equipment.

Study: Enhanced Performance With Long Lasting Components

Including resilient undercarriage parts has demonstrated significant enhancements in machinery efficiency. One study entailed a construction company that updated its excavator's undercarriage elements to more resilient options. The firm observed a significant decline in downtime as a result of undercarriage maintenance, leading to raised efficiency and cost financial savings. The long lasting components endured rough working problems, lowering damage substantially.

In great post to read another instance, a mining operation replaced the undercarriage components of its bulldozer with premium, long lasting choices. This switch caused an amazing renovation in the bulldozer's maneuverability and overall performance. The maker might browse difficult terrains more effectively, resulting in enhanced operational efficiency and minimized gas usage.

In addition, a logging firm spent in long lasting undercarriage components for its forestry devices. The updated elements exhibited prolonged life expectancy and enhanced resistance to abrasion from harsh surface. As a result, the firm experienced minimized maintenance prices and improved equipment uptime, ultimately enhancing its bottom line. These situation studies highlight the concrete benefits of utilizing durable undercarriage components in enhancing equipment efficiency and long life.

Final Thought

Finally, making use of durable undercarriage components can significantly improve efficiency and longevity of heavy equipment. Factors such as proper maintenance and choosing the appropriate components play an essential role in optimizing undercarriage durability. By carrying out these strategies, businesses can decrease downtime, rise efficiency, and eventually reduce functional prices. Instance research studies have actually revealed that buying sturdy undercarriage parts can result in boosted total efficiency and productivity in various markets.

The performance and effectiveness of these components can substantially affect the total procedure of machinery, making the selection of durable undercarriage components an essential decision for managers and operators alike.Including sturdy undercarriage parts has actually demonstrated substantial enhancements in equipment efficiency. These instance studies underscore the concrete benefits of utilizing durable undercarriage components in optimizing equipment performance and longevity.

In final thought, using durable undercarriage components can considerably improve performance and durability of heavy equipment (undercarriage parts). Instance research studies have revealed that spending in long lasting undercarriage parts can lead to enhanced overall efficiency and productivity in different sectors

Report this page